Applications And Design Of Plate Heat Exchanger

Plate heat exchangers are industrial devices used to transfer heat from one liquid to other fluids by intervening in metal plates. It is beneficial to be used for conventional heat exchangers because the liquid is related to a much larger surface area, partly because of the liquid that spreads to the plate. It really helps heat transfer and makes this very efficient device.

Design and Fabrication.

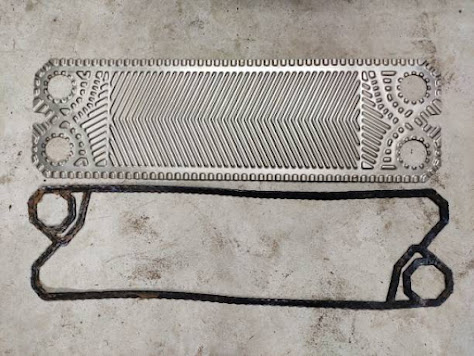

Plate heat exchangers are made of thin wavy plates that are stacked above or next to each other. Corrugation on the plate is designed in such a way that each plate will fit the next plate. Two parallel plates will make narrow space usually between 1.3 to 1.55 mm. The waves on the plate also provide a very large surface area in a compact room. It gives more contact fluid to the plate, facilitates heat transfer.

Room thinness also ensures that the majority of liquid volume will come into contact with plates, once again contributing to greater heat transfer. The plate is then sealed - welded, semi-welding or brazed together, depending on the desired application.

From the outside, all heat exchangers look very similar. The main difference is located inside, between the intricacies of dish designs and different sealing technology used. Different details on the plate will determine the ideal task for certain devices.

The correct heat exchanger is usually used for high pressure fluids or other operating modes that require smaller and more concise products. Larger mechanism, on the other hand, for general heat transfer purposes.

Plate is made of high quality metal; Stainless steel becomes a favorite material because of its strength, resistance to corrosion, and a high temperature threshold.

Industrial Application

It is used in many different applications, especially those dealing with fluids that need to be cooled or heated. Industries such as food, brewing, and pharmaceuticals, among others, all have places for heat exchangers plate in many of their production plants.

In this modern age industrialization, the process where a product is made as important, if it is no more important than the product itself. Minimizing costs and maximizing income is the saying that lives and operated by the company. That is why the manufacturing process efficiency is one of the main concerns of every good-meaning business. Which companies are willing to make profits must look into streamlining fabrication methods and invest in efficient technology to offset production costs.

And the truth of this problem is, heat exchanger plate is the most economical and efficient type of heat exchanger in the market with low costs, flexibility, easy maintenance, and high thermal efficiency.

Insurance Quality

When viewing heat exchangers plate, it is important to not only examine the products faced, but also evaluate the amount of research and development carried out by manufacturers and post-purchase services that they can offer. Right repair and maintenance must be in the realm of manufacturer's capacity. Also important is the availability of spare parts for damaged machines. If this is an integral part of your manufacturing process, then it is your best interest to keep them in optimal conditions.

.jpg)

Comments

Post a Comment