The Basics of Heat Exchangers

Heat exchangers are a staple in the present gadgets. They are not just present in the easiest of gadgets; exchangers have likewise tracked down their utilization in enormous ventures and hardware on the planet today. They are fundamentally gadgets found in certain machines that empower them to move heat starting with one medium then onto the next. They work with the proficient exchange of hotness starting with one article then onto the next.

Utilization of Heat Exchangers

One illustration of this is the radiators found in vehicles or climate control systems. What ordinarily happens is that a hotness source moves water that will cool the motor through the exchanger. The exchanger will move heat from the water to air leaving the motor cooler.

Heat exchangers are broadly utilized for the reasons for space warming, cooling, and even refrigeration. Substantial enterprises that additionally utilize this innovation incorporate power plants, compound and petrochemical plants, oil and oil treatment facilities, petroleum gas processors, and sewage treatment offices.

Kinds of Heat Exchange Flow

Heat exchangers can be grouped into two kinds, principally as indicated by their stream game plans. These are the equal stream and the counter-stream exchangers.

The equal stream trade includes the two mediums going in the exchanger through a similar side of the gadget. For instance, two liquids will enter the exchanger at a similar side and travel equal to each other for the entire cycle.

The counter-stream trade, then again, is something contrary to the main cycle. Here, liquids will enter the gadget from various closures and meet each other for the course of the hotness trade. Numerous exchangers utilize this stream since it has been demonstrated to be the more powerful of the two cycles since it can move additional hotness from the warming medium to the next. In this setup, the mediums travel to each other and are then handled by the exchanger.

Generally, exchangers are planned such that the surface region between the two trading liquids is amplified while limiting the protection from the trade stream simultaneously. Extra balances introduced in either course where the liquids enter can likewise improve exchangers. These blades can add to the surface space of the exchangers while additionally helping control the progression of liquids during the trade interaction.

The temperature during the Heat Exchange Process

Contingent upon the size of the exchanger, the temperature will fluctuate during the trade interaction. The temperature will likewise fluctuate as indicated by the situation of the gadget. In any case, numerous ventures that utilization exchangers quite often have their own characterized mean temperature.

This temperature is normally characterized as far as the Log Mean Temperature Difference or the LMTD. In some cases however the temperature is still difficult to decide through the LMTD strategy, for this situation, the NTU technique is then utilized.

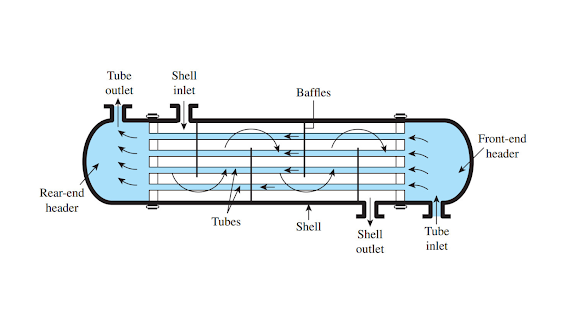

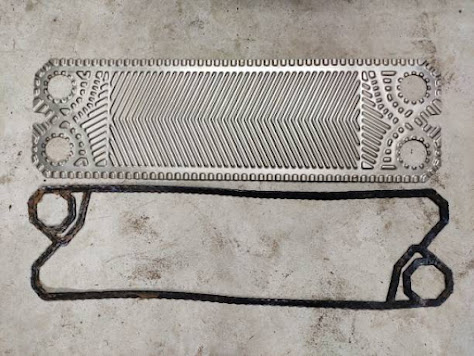

Sorts of Heat Exchangers

There are a few sorts of Heat exchangers utilized today. These incorporate shell tube exchangers, plate exchangers, adiabatic wheel, plate balance, liquid exchangers, dynamic scratched surface, stage change exchangers, HVAC air loops, twisting exchangers, and the immediate contact exchangers.

We’ve talked about the importance of custom heat exchangers for your business, but what if you need help finding an experienced company to work with? Our team has experience working within many industries and can guide you in selecting a great shell and cylinder heat exchanger producer that will provide quality products. Contact us today to learn more!

.jpg)

Comments

Post a Comment