Spiral Heat Exchangers

There are many types of heat exchangers that are already on the market today. Most of them are used in our daily devices while some of them play a more specific role in machines used in heavy and business industries. These products are needed mainly for machines used for hours because they are constantly needing to be cooled to maintain their efficiency in business processes.

One type commonly used today is spiral heat exchanger, also known as him. This circular tube setting feature that can usually be seen is installed on a flat surface that circles in such a way that two channels will display counter-stream settings. Each channel has a curved path where the media usually goes during the exchanging heat process.

The Advantage Using Him

Efficiency in distance is the main sales point of spiral heat exchangers. This space can also be upgraded and configured to provide more efficiency during the exchange of heat processes. The developer can really change their design a little to maximize their heat exchanger design.

These types can be used to reduce capital costs and get a smaller trace in your process. A large on the other hand can be used by businesses who are aware of their energy costs and want their business aspects to be lower. Larger dresses produce less pressure and pump energy so that it uses lower energy when operating.

Spiral Heat Exchanger Settings

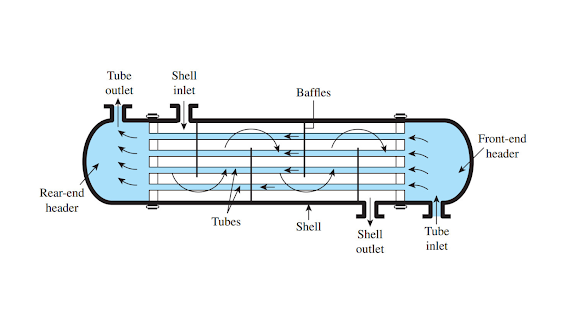

Spiral heat exchangers are built in such a way that they will maximize space and efficiency when used. The spiral channel used by it is usually separated by the use of a spacer stud. After this was done, a closed heat exchanger after the main spiral tube was placed.

Cover welded and then attached using a flat gasket or cone cover on the body. It efficiently separates the two media involved during the heat process exchange. This setting also avoids leakage. Because the liquid is usually the process combined with some solids, the tendency for this usually causes the smell on the machine. But lower pressure where spiral heat exchangers work by allowing it to survive against fouling is more efficient than other types of heat exchangers.

Setting him also helped him in fighting the rotten substances trapped during the process. The rotten surface in the device increases the speed of the liquid and thus produces fluid friction which ultimately clears the sacrificial parts of the device. This special feature can be dubbed as its own cleaning feature.

Additional Information

There are three main types currently produced by him. This is the flow of Councurrent, cross flow and steam flow distributed.

Because he regulates and has the ability to create various types of flow in the process, they are widely used by companies involved in the Digester heating business, heat recovery, recovery, waste cooling and even pasteurization. It can also be used for waste and mud care. In this case, spiral heat exchangers are usually smaller.

.jpg)

Comments

Post a Comment