Design and Industry Applications of Plate Heat Exchangers

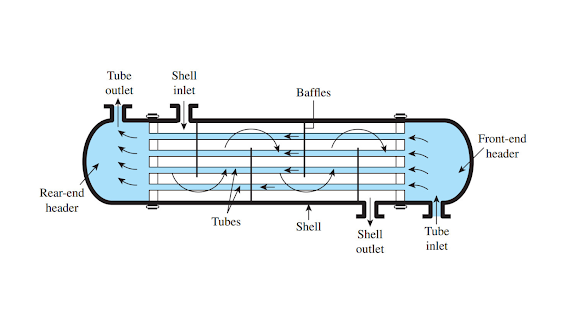

Plate heat exchanger are modern gadgets used to move heat starting with one fluid then onto the next via interceding metal plates. It is beneficial to involve over regular intensity exchangers in that the liquids are in touch to a lot bigger surface region, due to some extent to the fluid fanning out over the plates. This extraordinarily helps with the exchange of intensity and makes these extremely effective gadgets.

Plan and Fabrication

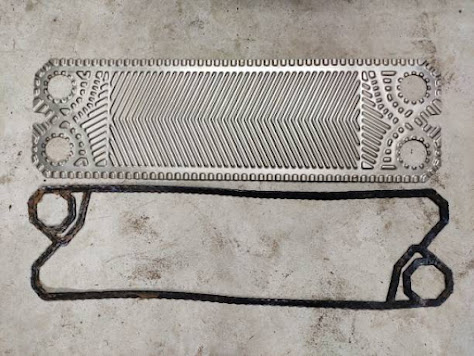

Plate heat exchangers are produced using slight creased plates heaped on top or close to each other. The layerings on the plate are planned so that each plate would fit cozily onto the following plate. Two equal plates would make a limited chamber ordinarily between 1.3 to 1.55 mm thick. The grooves on the plate additionally give it an exceptionally huge surface region in a smaller space. This gives the fluid more contact to the plate, working with heat move.

The slimness of the chambers additionally ensures that most of the volume of the fluid would come into contact with the plate, again adding to more prominent intensity move. The plates are then fixed - welded, semi-welded or brazed together, contingent upon the ideal application.

From an external perspective, all plate heat exchangers look basically the same. The primary distinction exists in, among the complexities of the plate plan and the different fixing advances utilized. The various subtleties on the plates would decide the best assignment for a particular gadget.

Brazed heat exchangers are typically utilized for high strain fluids or different methods of activity requiring a more modest and more reduced item. Bigger systems, then again, are for general intensity move purposes.

The plates are produced using top notch metals; treated steel being a most loved material because of its solidarity, protection from erosion, and high temperature limit.

Industry Applications

These are utilized in various applications, especially those managing liquids that should be cooled or warmed. Businesses like food, fermenting, and drugs, among others, all have a spot for plate heat exchangers in their numerous creation plants.

In this advanced time of industrialization, the cycle by which an item is made is as significant, while possibly not a higher priority than the actual item. Limiting expenses and expanding income is an aphorism that organizations live and work by. For that reason the effectiveness of the assembling system is one of the essential worries of any benevolent business. Any organization able to create a gain ought to investigate smoothing out manufacture techniques and putting resources into proficient innovation to counterbalance producing costs.

Also, reality of the situation is, plate heat exchangers are the most practical and effective sort of intensity exchanger available with its minimal expense, adaptability, simple upkeep, and high warm proficiency.

Quality Assurance

While seeing plate heat exchangers, it is critical to examine the current item, yet in addition assess how much innovative work led by the maker and the degree of post-buy administration they can offer hairpin heat exchangers. Fixes and legitimate upkeep should be inside the domain of the maker's ability. Additionally significant is the accessibility of extra parts for harmed machines. On the off chance that these are a basic piece of your assembling interaction, it is to your greatest advantage to keep them in ideal condition.

.jpg)

Comments

Post a Comment