Understanding and Avoiding Costly Heat Exchanger Failures

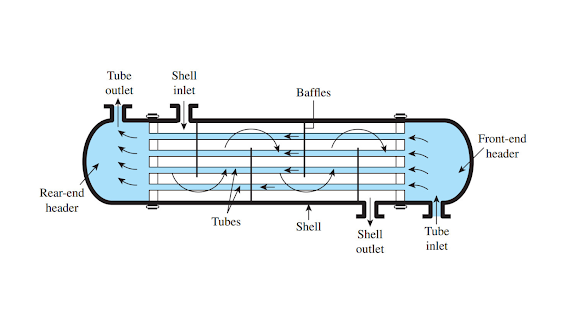

Heat exchangers are responsible for exchanging heat between two different fluids or gases. In order to do their job properly, heat exchanger parts must be able to withstand a great deal of heat and pressure. However, if these devices fail, it can lead to costly consequences for both your business and the environment. In this article, we'll take a look at some of the most common types of heat exchanger failures, and discuss ways to prevent them from happening in the first place.

What are Heat Exchanger Failures?

Heat exchangers are important devices in any industrial or commercial setting that need to regulate the temperature of fluids. However, they can also be very costly to maintain and repair if they fail. When a heat exchanger fails, the increased temperature of one fluid can cause the other fluid to boil or vaporize, potentially causing serious property damage and even injuries.

There are many signs that a heat exchanger may be failing. If you see any of these symptoms, it is important to contact a professional inspector as soon as possible to determine the extent of the problem and take appropriate steps to address it. Some common signs of a failing heat exchanger include:

Boiling or Vaporizing Fluid Signs:

-Fluid temperatures reaching levels that would normally only be seen with boiling water

-VAP (vaporized liquid) build-up on equipment surfaces

-Structural damage from excessive heating

Failure Modes:

-Intermittent or continuous failure of one or more component parts

-Foreign object ingestion into the cooling system

-Leakage of hot fluid from the heat exchanger

Types of Heat Exchanger Failures

There are a few types of heat exchanger failures that can occur in an HVAC system. The most common failure is the condenser fan motor failing, which can cause the condenser to overheat and fail. Other common failures include the evaporator fan motor failing, the water pump failing, or the pipe insulation breaking down.

To avoid costly heat exchanger failures, it is important to understand the basics of how heat exchangers work and what can go wrong. Heat exchangers use a fluid to transfer thermal energy from one area to another. In an air-conditioning system, for example, the air entering the system is heated by the furnace and then transferred through the compressor, condenser, and radiator to reach room temperature. The coolant (water in this case) circulates around these components and returns hot water back to the furnace.

If any of these components fail, it will cause problems with heat exchange and eventually lead to an overheat or failure. It is important to keep an eye on your system’s overall health – if something seems off, be sure to investigate what might be causing it. By following these tips, you can help avoid costly heat exchanger failures in your HVAC system!

Causes of Heat Exchanger Failures

The most common causes of heat exchanger failures are clogging, corrosion, and thermal overload. Clogging can be caused by dirt, debris, or foreign objects that get lodged in the exchanger’s openings. Corrosion can occur when water droplets combine with pollutants in the water to form corrosive compounds. Overloading can occur when the exchanger is unable to handle the increased flow rates caused by an increase in temperature or humidity.

Preventing Heat Exchanger Failures

Heat exchangers are an important part of any cooling or heating system. However, they can also fail, costing you money in the process. Here are some tips to help prevent costly heat exchanger failures.

1. Keep your system well-maintained: A poorly maintained cooling or heating system is more likely to experience a heat exchanger failure. Regularly check your HVAC unit for broken or clogged tubing, and clean out any debris buildup.

2. Use quality parts: When it comes to heat exchangers, make sure you're using quality parts that are compatible with your system. Poor-quality heat exchangers can wear quickly, leading to costly repairs or replacements down the road.

3. Regularly monitor your system: always keep an eye on your system's temperature and pressure gauges to ensure everything is running smoothly. If something seems off, take a look at your heat exchanger to see if there's a problem.

4. Check for leaks: one of the most common causes of heat exchanger failure is leakage from the unit itself. Make sure all seams and joints are properly sealed and check for signs of water infiltration (leaks). If you do find a leak, address it immediately!

Conclusion

It is important to understand the signs and symptoms of a costly heat exchanger failure, so that you can take steps to prevent them from occurring. By following these tips, you can ensure that your cooling and heating systems are operating at their best possible efficiency, reducing your overall energy costs.

.jpg)

Comments

Post a Comment