All About Plate Heat Exchangers - What You Need To Know

When it comes to industrial processes, heat is key. Without it, many tasks would be impossible, from production to distribution. In this blog post, we will explore the basics of plate heat exchangers and what you need to know in order to choose the best one for your needs. With the right heat exchanger, you can optimize processes and boost efficiency across a wide range of industries. so read on to learn all you need to know about this crucial component of industrial machinery.

What are Plate Heat Exchangers?

A plate heat exchanger is a machine that uses the exchange of thermal energy between two fluids to improve process efficiency and economy. Plate heat exchangers are most commonly used in manufacturing and processing plants to decrease the amount of energy needed to move fluid temperatures between different sections.

The technology of plate heat exchangers has evolved significantly over the years, with today’s exchangers using large plates that can handle high flow rates. These exchangers are typically mounted in horizontal or vertical configurations, allowing them to be easily incorporated into facility layouts. In addition, modern plate heat exchangers often feature modular construction, which makes them easy to replace and upgrade as necessary.

Types of Plate Heat Exchangers

There are three main types of plate heat exchangers: fixed-plate, fluidized-bed and pressure-flow.

Fixed-plate heat exchangers use metal plates that are stationary and remain in the same location throughout the exchanger's life. These exchangers are often used to transfer large amounts of thermal energy between two fluids.

Fluidized-bed heat exchangers use a bed of heated particles that move around randomly, allowing for more efficient transfer of thermal energy. This type of exchanger is often used to transfer small amounts of thermal energy between two fluids.

Pressure-flow heat exchangers use a pressurized fluid to move the hot and cold liquids through the machine. This type of exchanger is often used to transfer thermal energy between two gases.

Benefits of using a Plate Heat Exchanger

There are many benefits of using a plate heat exchanger, including:

- Reduced energy costs - Plate heat exchangers can help reduce energy costs by exchanging thermal energy between two systems.

- Improved efficiency - By exchanging thermal energy more efficiently, plate heat exchangers can improve the efficiency of a system. This can lead to decreased emissions and decreased fuel consumption.

- Reduced environmental impact - Plate heat exchangers can play an important role in reducing environmental impact by reducing the amount of air pollution and water contamination produced by systems.

How to Choose the Right Plate Heat Exchanger

When choosing a plate heat exchanger, there are a few things to consider. The type of fluid being cooled and the configuration of the exchanger will affect the required size, shape, and material of the exchanger.

The fluid to be cooled - water, oil, or gas - will determine what kind of exchanger is needed. A plate heat exchanger for water cooling is different from one for oil or gas cooling. In all cases, however, a suitable exchanger needs to be able to operate at high temperatures (up to 1,000 degrees Celsius).

The configuration of the exchanger also affects its size and shape. A typical water-cooled exchanger has many plates that can be rotated. This allows more direct contact between the coolant and the heated element, which results in better thermal efficiency. For oil cooling, on the other hand, a single large plate with fins is usually sufficient. Gas-cooled exchangers are similar to oil-cooled ones but have no moving parts; they use radiation pressure to transfer heat from one side of the exchanger to the other.

How Do They Work?

When the engine starts up, all of the fluid inside it is at room temperature. The oil and coolant flow through the engine and start to reach temperatures around 200 degrees Fahrenheit (93 degrees Celsius). This high temperature causes the oil and coolant to start separating into different phases.

In a typical engine, most of the work happens in the first 100 degrees Fahrenheit (38 degrees Celsius). At this point, the oil has mostly condensed into small droplets and starts to solidify. Meanwhile, the coolant has turned into a thick liquid form.

The phase separation process continues as the temperatures continue to rise. By 250 degrees Fahrenheit (121 degrees Celsius), almost all of the oil has solidified while almost all of the coolant remains liquid.

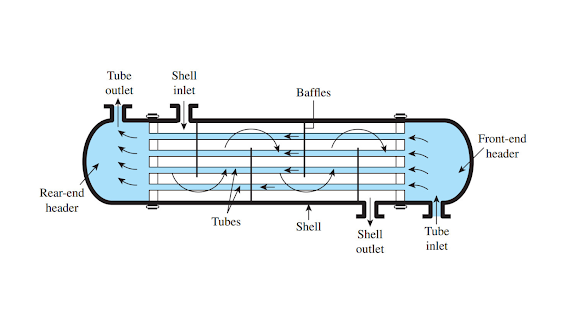

This is where a plate heat exchanger comes in handy. It's basically a large tray filled with metal plates that are spaced slightly apart. When the engine starts up, the hot oil and coolant flow through the heat exchangers and reach temperatures near the engine's pistons.

The metal plates in the heat exchanger act as a thermally efficient heat exchanger. This means that they can transfer a lot of thermal energy from one fluid to another.

How Do I Install a Plate Heat Exchanger?

There are a few different ways that you can install a plate heat exchanger in your engine. The most common way is to use an existing hole in your engine block. You can also buy a pre-made plate heat exchanger kit or build your own.

If you're installing a plate heat exchanger using an existing hole in your engine block, you'll first need to remove the old radiator and fan assembly. This will allow you to access the space where the new heat exchanger will be installed.

Next, you'll need to drill an extra large hole in the engine block specifically for the new heat exchanger. You'll also want to make sure that the hole is big enough so that the plates of the heat exchanger can fit easily inside it.

Once you have drilled the hole, it's time to install the plates of the heat exchanger.

Conclusion

If you're in the market for a new heating and cooling system, it's important to understand what plate heat exchangers are and what they can do for your home. Plate heat exchangers are versatile devices that can be used to improve the efficiency of any heating or cooling system, making them an ideal choice for homes with large rooms or high energy usage. This heat exchanger is the most efficient in the industry. If you're interested in learning more about this type of technology, read on for all the information you need to make an informed decision.

.jpg)

Comments

Post a Comment