Heat exchangers are an essential component in many industrial processes that require efficient heat transfer. TEMA heat exchangers are a type of shell and tube heat exchanger that follow the standards set by the Tubular Exchanger Manufacturers Association (TEMA). In this blog, we will explore the unique features of

TEMA heat exchanger, their applications, and the benefits they offer over other types of heat exchangers.

What are TEMA Heat Exchangers?

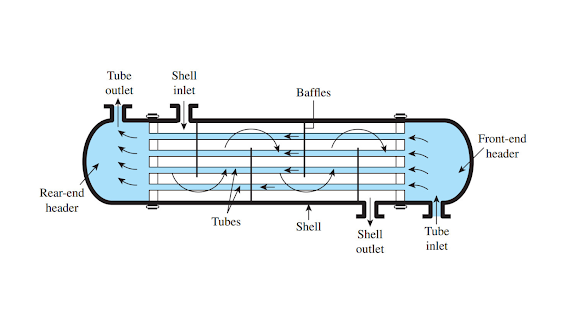

TEMA heat exchangers are a type of shell and tube heat exchanger that follow the standards set by the Tubular Exchanger Manufacturers Association (TEMA). They consist of a bundle of tubes that are mounted inside a shell. The fluid to be heated or cooled flows through the tubes, while the fluid providing or receiving heat flows around the tubes in the shell.

Applications of TEMA Heat Exchangers

TEMA heat exchangers are used in a wide range of applications, including:

- Power generation: TEMA heat exchangers are used in power plants to transfer heat from steam to water, or from hot gas to water.

- Chemical processes: They are used in chemical plants to cool or heat process fluids.

- HVAC systems: TEMA heat exchangers are commonly used in HVAC systems to transfer heat between the air and a refrigerant.

- Oil and gas industry: They are used in the oil and gas industry for cooling or heating fluids and gases.

Advantages of TEMA Heat Exchangers

TEMA heat exchangers offer several advantages over other types of heat exchangers, including:

- High efficiency: TEMA heat exchangers have a large surface area for heat transfer, resulting in high heat transfer rates and improved efficiency.

- Customizable design: TEMA heat exchangers can be designed to handle a wide range of flow rates, temperatures, and pressures, making them ideal for a variety of applications.

- Easy to clean: TEMA heat exchangers can be easily cleaned using a high-pressure water jet or a chemical cleaning solution.

- Durable construction: TEMA heat exchangers are constructed from high-quality materials, ensuring long-lasting performance and reliability.

Conclusion

TEMA heat exchangers are a highly efficient and versatile solution for heat transfer in many industrial processes. They offer several advantages over other types of

heat exchangers, including a customizable design, high efficiency, and easy maintenance. The TEMA standards ensure that these heat exchangers meet strict quality and performance standards, ensuring reliable and long-lasting performance. With their broad range of applications, TEMA heat exchangers are an excellent choice for industries looking to optimize their heat transfer processes.

.jpg)

Comments

Post a Comment