Why Thermal Fluid Heaters are the Best Choice for Industrial Applications

As industries continue to grow and evolve, the demand for reliable and efficient heating solutions is on the rise. Thermal fluid heaters have become increasingly popular in industrial applications due to their ability to handle a wide range of temperatures and deliver consistent heat transfer. In this blog post, we'll explore why thermal fluid heaters are the best choice for industrial applications and how they can help businesses improve their operations while reducing costs. Get ready to learn about the benefits of this innovative technology that's changing the game for companies around the world!

What is a thermal fluid heater?

Thermal fluid heaters are the best choice when you need a reliable, efficient heating solution for industrial applications. They can withstand high temperatures and are often used in manufacturing and processing plants. Thermal fluid heaters use liquid or gas to transfer heat, and they are very versatile. They can be used to heat liquids or gases, and they are also easy to install and operate.

Some of the benefits of using a thermal fluid heater include:

They are reliable.

They are efficient.

They are easy to install and operate.

Advantages of using thermal fluid heaters

Thermal fluid heaters are the best choice for industrial applications because of their many advantages. These heaters use a unique type of heat transfer that is more efficient than other methods, making them a good choice for high-heat industrial applications. They also have low operating costs and are easy to maintain. Thermal fluid heaters also have many safety features, such as automatic shutdown in the event of an emergency.

Some of the advantages of using thermal fluid heaters include:

1. They are more efficient than other types of heaters.

2. They have low operating costs.

3. They are easy to maintain.

4. They have many safety features, such as automatic shutdown in the event of an emergency.

Types of thermal fluid heaters

There are many types of thermal fluid heaters, but the most common are oil-fired or gas-fired. Oil-fired heaters use a hot furnace to generate heat from burning oil. Gas-fired heaters use hot gas from a burner to produce heat.

The three main advantages of thermal fluid heaters over other heating systems are that they are:

1) Sustainable – Thermal fluid heaters do not produce greenhouse gases like coal or gas plants do.

2) Efficient – Thermal fluid heaters use less energy than other heating systems and can be more affordable in some cases.

3) Portable – Thermal fluid heaters can be moved around as needed, making them perfect for industrial applications.

There are several types of thermal fluid heaters, each with its own advantages and disadvantages.

Oil-fired or gas-fired thermal fluid heaters use hot gas from a burner to produce heat. The main advantage of gas-fired thermal fluid heaters is that they are more efficient than oil-fired thermal fluid heaters. They also have the advantage of being portable, which is perfect for industrial applications. However, gas-fired thermal fluid heaters are more expensive to operate than oil-fired thermal fluid heaters.

Applications for thermal fluid heaters

Thermal fluid heaters are a very versatile and reliable choice for industrial applications because of their high energy density, low noise levels, and long lifespan. They can be used in a variety of industries, including petrochemical, food processing, pharmaceuticals, and mining. Thermal fluid heaters have several advantages over other heating methods: they are easy to install and maintain, they produce little noise or fumes, and they have a long lifespan.

One of the most important factors to consider when choosing a thermal fluid heater is its energy density. Heaters with a high energy density produce more heat per unit of fuel than lower-energy models. This means that thermal fluid heaters can run longer without having to be replaced or refueled. In addition, thermal fluid heaters are less likely to create environmental problems than other heating methods. They produce very little noise or fumes, and they do not require any special ventilation systems.

Another important factor to consider when choosing a thermal fluid heater is its lifespan. Heaters with a longer lifespan require less maintenance overall than those with shorter lifespans. They also produce less noise and fumes over the course of their lifetime, meaning that they pose fewer environmental concerns. In addition, thermal fluid heaters typically have a longer warranty period than other heating methods. This makes them an ideal choice for businesses that want to invest in a reliable heating solution that will last for years instead of months or weeks.

Conclusion

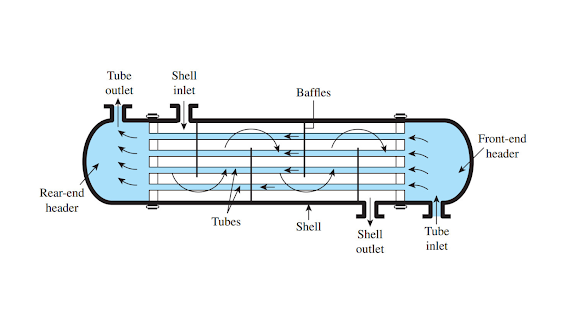

Thermal fluid heaters are the best choice for industrial applications because they offer reliable, consistent heat and have a long lifespan. They can also be mounted in any position, making them ideal for applications where space is at a premium. In addition, tema heat exchanger are very efficient and produce very little noise, making them perfect for use in sensitive environments. If you are looking for a reliable and cost-effective heating solution for your industrial application, thermal fluid heaters should definitely be on your list of options.

.jpg)

Comments

Post a Comment